| Activated Carbon is a form of carbon that is activated by a carefully controlled oxidation process to develop a porous carbon structure. The imperfect structure results in a high degree of porosity and over a broad range of pore sizes, from visible cracks and crevices to gaps and voids of molecular dimensions. The specified structure of carbon gives it a very large surface area which allows the carbon to adsorb a wide range of compounds. Activated carbon has the highest volume of adsorbing porosity of any material available to mankind. |

|

To put this into perspective, 5gms of Activated carbon would have the surface area of a football field |

Activated carbon can be made from many substances containing high carbon content such as coconut shells, coal and wood. The raw material has a very large influence on the characteristics and performance of activated carbon and plays a major part in determining it’s ability to adsorb certain molecular species. |

Forms of activated carbon:

Three main forms of activated carbon are

|

| Granular Activated Carbon -

Irregular shaped particles with sizes ranging from 0.2 to 5 mm. |

| Powder Activated Carbon - Carbon with a size predominantly less than 0.21mm (70 US mesh) |

| Pelleted Activated Carbon - Extruded and cylindrical shaped with diameters from 0.8 to 5 mm. |

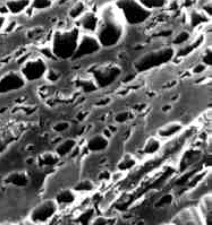

| Structure of Activated Carbon: |

Three groups of pores can be distinguished in Activated carbon

|

Pore structure – A closer look |

| • Micropores having radius less than 1nm |

| • Mesopores having radius 1 - 25nm |

| • Macropores having radius greater than 25nm |

| The major portion of the surface area is derived from the small diameter micropore and the medium diameter mesopore regions. Micropores have been found to be the most effective in trapping small molecules in gas and liquid phase applications. |

| The mesopore region is most suitable for adsorbing large molecular species such as colour molecules. Activated carbons produced from coconut shells exhibit a predominance of micropores, while coal based carbons have a wider range of mesopores. The development of an extensive macropore structure is found when either peat or wood is used as the raw material. |

| Production and Processing Techniques: |

|

There is a wide variety of production and processing techniques used in the manufacture of activated carbons depending on the type of the raw material being used and the physical form of activated carbon required. |

Steam Activation : This technique is generally used for the activation of coconut shell raw material. Activation is carried out at temperatures around 900°C in the presence of steam. Initially, a reaction of the carbonised material with steam occurs, known as the Water-Gas reaction :- C + H20 -> CO + H2 -175,440 kJ/(kg mol) |

This reaction being endothermic, temperature is maintained by partial burning of the CO and H2 formed:-

|

2CO + O2 -> 2CO2 +393,790 kJ/(kg mol)

2H2 + O2 -> 2H2O +396,650 kJ/(kg mol) |

|

| The air is added proportionally so as to burn the gases without burning the carbon. |

Adsorptive Characteristics :

The effectiveness of Activated carbon is usually specified by the amount of a certain test chemicals it can adsorb per unit weight of activated carbon used. |

CTC Activity : For Activated carbon used for filtering air and gases, the test chemical used is usually Carbon Tetrachloride, commonly designated as CTC and is specified as CTC Activity (%). In some areas, this test is being substituted by a similar test which uses n-butane, known as the Butane Number Test. To obtain the Butane Number from Carbon Tetrachloride Number, divide the Carbon Tetrachloride Number by 2.55. |

Iodine No. : For activated carbon used in filtering water and liquids, the test chemical used is usually Iodine mixed with water and is specified as Iodine no. (mg/gm) of carbon. |

Surface Area : Measurement of the extent of the pore surface developed within the matrix of the activated carbon. The BET N 2 method, using nitrogen measures the area by determining the amount of liquid nitrogen needed to evenly cover all the surface in these holes. This is used in activated carbon research and is not a practical method to be used as a quality control tool. |

The Iodine Number and the CTC Activity, both of which measure the adsorption capacity, are generally used to monitor quality during production and use. |

Physical Characteristics : |

Hardness : The harder the activated carbon, the less it will crumble into fine particles during handling and use. This value gives an idea of the abrasion-resistance of the activated carbon and is measured by means of a ball pan. Coconut shell based Activated Carbon has the unique property of the highest hardness ( over 99%) which increases the durability and reduces loss in application, handling and regeneration. |

Apparent Density : Is the weight of one litre of Activated carbon (g/ltr). Density depends on the raw material being used and the degree of activation. The density does not affect the effectiveness of the activated carbon measured in adsorption per unit weight, but will have an effect on adsorption per unit volume. |

Ash Content : This is the inorganic, inert, amorphous and unusable part present in the activated carbon. This ash comes initially from the basic material. Lower the ash content, the better the activated carbon. The practical limit for the level of ash content allowed in the activated carbon varies within 2 to 5%. |

Moisture : This is the amount of water physical bound on the activated carbon under normal condition. The practical limit for the level of moisture content allowed in the activated carbon varies within 3 to 6%. |

pH Value : The pH Value of activated carbon is a measure of whether it is acidic or basic. Coconut shell based Activated Carbon normally is specified for a pH of 9 – 11. |

Particle Size Distribution : Activated carbons are available in a wide range of granular and powdered grades. The particle size distribution of a grade is defined using test sieves. Different particle size of activated carbon offer different flow resistance to the air or water it is filtering. Depending upon the situation, system designers will specify different particle sizes of the activated carbon to be used. Typically, for filtering air or gases, the larger granule sizes are used; for filtering water or fluids, the smaller granule sizes are used. |

| |